In today’s fast-moving global supply chain, maintaining product quality from origin to destination is more important than ever. Industries such as pharmaceuticals, food & beverages, healthcare, agriculture, and biotechnology rely heavily on cold chain transportation services to preserve product integrity, safety, and shelf life.

This comprehensive guide explains what cold chain transportation is, how it works, why it is critical, and how businesses can choose the right cold chain logistics solutions for their needs.

What Are Cold Chain Transportation Services?

Cold chain transportation services refer to the movement of temperature-sensitive goods through a controlled supply chain environment. This process ensures that products remain within a specific temperature range during storage, handling, and transit.

These services typically use:

- Refrigerated trucks (reefer vehicles)

- Insulated containers

- Temperature monitoring systems

- Cold storage warehouses

The objective is simple: prevent temperature fluctuations that could compromise product quality or safety.

Why Cold Chain Transportation Is Essential

Many products degrade or become unsafe when exposed to temperatures outside their recommended range. Cold chain logistics prevents:

- Bacterial growth

- Chemical degradation

- Physical damage

- Loss of potency (especially in pharmaceuticals)

Key benefits include:

- Extended product shelf life

- Reduced spoilage and waste

- Compliance with regulatory standards

- Increased customer trust

Industries That Depend on Cold Chain Transportation

1. Pharmaceutical & Healthcare Industry

Medicines, vaccines, blood samples, and biological products require precise temperature controlled transport. Even small deviations can render products ineffective.

2. Food & Beverage Industry

Fresh produce, frozen foods, dairy products, meat, and seafood rely on chilled goods transport services to maintain freshness.

3. Agriculture Sector

Seeds, flowers, fruits, and vegetables require cold chain support to reach markets in optimal condition.

4. Biotechnology & Research

Laboratory samples, enzymes, and reagents depend on reliable cold chain logistics services.

Types of Cold Chain Transportation

Refrigerated Road Transport

The most common form of cold chain transport using reefer trucks with adjustable temperature zones.

Cold Chain Sea Freight

Used for international shipments of frozen or chilled goods in refrigerated containers.

Air Cargo Cold Chain

Ideal for high-value or time-sensitive temperature-sensitive shipments.

Rail-Based Cold Chain Transport

Cost-effective for large volumes over long distances.

Temperature Ranges in Cold Chain Logistics

Different products require different temperature ranges:

- Frozen: -18°C and below

- Chilled: 0°C to 4°C

- Cool: 8°C to 15°C

- Controlled Room Temperature: 15°C to 25°C

Modern multi-temperature vehicles allow transportation of multiple product types in a single trip.

Key Components of a Reliable Cold Chain System

1. Refrigerated Vehicles

Well-maintained vehicles with efficient cooling systems.

2. Cold Storage Warehouses

Strategically located facilities for pre-cooling, storage, and dispatch.

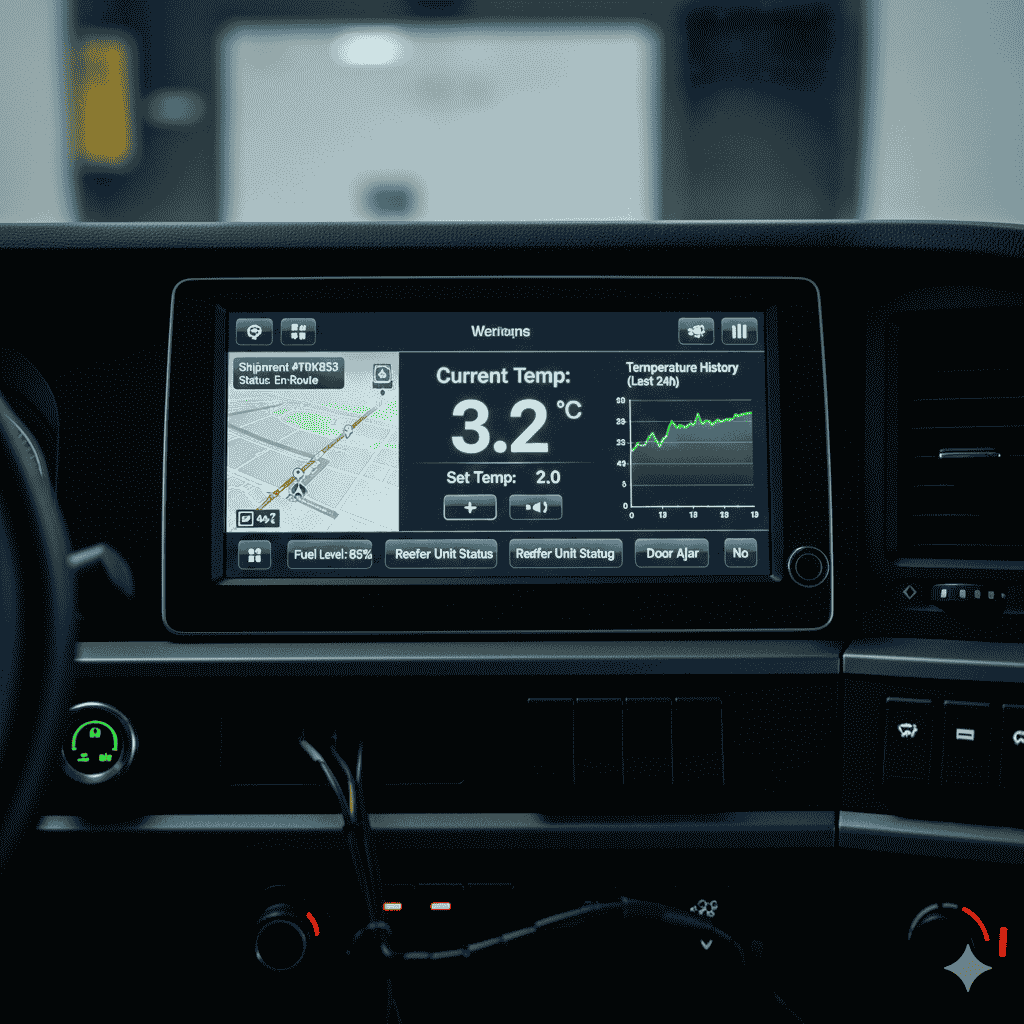

3. Temperature Monitoring Technology

Real-time sensors, data loggers, and alerts.

4. Trained Personnel

Staff trained in handling temperature-sensitive cargo.

5. Standard Operating Procedures (SOPs)

Clear protocols for loading, unloading, and emergency response.

How Technology Enhances Cold Chain Transportation Services

Modern cold chain operations are driven by advanced technology:

- GPS-enabled refrigerated trucks

- Real-time temperature monitoring

- Cloud-based reporting dashboards

- Automated alerts for deviations

- IoT-enabled sensors

These tools ensure transparency, traceability, and compliance.

Benefits of Professional Cold Chain Transportation Services

- Reduced product loss

- Improved delivery accuracy

- Regulatory compliance

- Consistent product quality

- Higher customer satisfaction

Businesses that invest in professional cold chain logistics solutions gain a strong competitive advantage.

Challenges in Cold Chain Transportation

Despite technological advancements, challenges remain:

- Power failures

- Equipment malfunction

- Human error

- Traffic delays

- Improper packaging

Reliable service providers mitigate these risks through preventive maintenance, backup systems, and staff training.

Packaging Solutions for Cold Chain Transport

Packaging plays a critical role in maintaining temperature:

- Insulated boxes

- Gel packs

- Dry ice

- Vacuum-sealed containers

- Phase change materials

Choosing the right packaging complements refrigerated transportation.

Regulatory Compliance in Cold Chain Logistics

Cold chain providers must comply with various standards such as:

- Good Distribution Practices (GDP)

- Food Safety regulations

- Pharmaceutical storage guidelines

- Local transport safety laws

Compliance ensures legal safety and product reliability.

How to Choose the Right Cold Chain Transportation Partner

When selecting a provider, consider:

- Experience in your industry

- Fleet quality and capacity

- Technology infrastructure

- Coverage area

- Certifications and compliance

- Customer reviews

A dependable cold chain service provider becomes a long-term logistics partner.

Cold Chain Transportation for Small & Medium Businesses

SMEs often assume cold chain services are expensive, but many providers offer scalable and cost-effective solutions such as:

- Shared refrigerated vehicles

- Pay-per-use storage

- Flexible routes

- Short-term contracts

This makes cold chain logistics accessible to growing businesses.

Sustainability in Cold Chain Logistics

Green cold chain practices include:

- Energy-efficient refrigeration systems

- Alternative fuels

- Route optimization

- Eco-friendly packaging

Sustainable logistics reduces environmental impact and operating costs.

Future Trends in Cold Chain Transportation Services

- AI-powered route optimization

- Autonomous refrigerated vehicles

- Blockchain for traceability

- Smart packaging with sensors

- Increased use of renewable energy

These trends will further strengthen cold chain reliability.

Why Businesses Should Invest in Cold Chain Transportation

Cold chain transportation is not just a logistics function—it is a quality assurance system. Whether you deal in pharmaceuticals, food, or biological materials, dependable temperature controlled logistics solutions protect your brand reputation and customer trust.

Final Thoughts

Cold chain transportation services form the backbone of modern supply chains for temperature-sensitive products. By combining advanced technology, skilled manpower, and robust infrastructure, businesses can ensure safe, efficient, and compliant delivery of perishable goods.

Choosing the right cold chain partner today means safeguarding your products, customers, and brand tomorrow.

FAQs

Q1. What is cold chain transportation?

Cold chain transportation involves moving temperature-sensitive goods under controlled conditions to maintain quality and safety.

Q2. Which products require cold chain logistics?

Pharmaceuticals, vaccines, frozen foods, dairy, seafood, fresh produce, and biotech samples.

Q3. What temperature is maintained in cold chain transport?

Depending on the product, from -18°C (frozen) to 25°C (controlled room temperature).

Q4. How is temperature monitored during transit?

Using real-time sensors, GPS tracking, and data loggers.

Q5. How do I choose a reliable cold chain service provider?

Look for experience, certifications, technology support, and positive client feedback.